CNC & RELATED EQUIPMENT

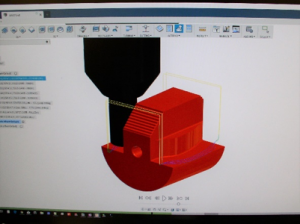

CAD/CAM Software

1) Seat Solidworks 2018

4) Seats Fusion 360 CAD/CAM software

2) Seats Fusion 360 Ultimate

5) Seats EZ-CAM CAM software

5) Seats VersaCad 2d drafting software

Support for conversion of DXF. and IGES.

1) Plotter – H.P. Model T120 “A” – “D” size

Equipment – CNC Vertical Mills

1) Leadwell V-40iT 5 Axis machining center

travel: X=40”, Y=25”, Z-21”

table/work piece 14”/24” Dia. 14” high

tool carousal: 30 tools at max dia of 3.0”

spindle RPM = 12,000, HP = 30

1) Leadwell V-40iT 5 Axis machining center

travel: X=40”, Y=25”, Z-21”

table/work piece 14”/24” Dia. 14” high

tool carousal: 40 tools at max dia of 3.0”

thru spindle coolant

spindle RPM = 12,000, HP = 30

1) Leadwell V-50i machining center

with 4th axis indexer & trunnion

table size = 56” X 24”

travel: X=50”, Y=25”, Z=24”

tool carousal: 30 tools at max dia of 3.0”

spindle RPM = 12,000, HP = 30

1) Leadwell V-50i machining center

table size = 56” X 24”

travel: X=50”, Y=25”, Z=24”

tool carousal: 30 tools at max dia of 3.0”

spindle RPM = 12,000, HP = 30

1) Leadwell V-42AF machining center

table size = 43” X 20”

travel: X=40”, Y=20”, Z=24”

tool carousal: 24 tools at max dia of 3.0”

thru spindle coolant

spindle RPM = 10,000, HP = 34

1) Leadwell V-42AF machining center

table size = 43” X 20”

travel: X=40”, Y=20”, Z=24”

tool carousal: 24 tools at max dia of 3.0”

spindle RPM = 10,000, HP = 34

1) Bridgeport Interact 720 machining center

table size = 46″ X 20″

travel: X = 30″, Y = 16.1″, Z = 17.7″

tool carousal: 20 tools at max dia of 3.0″

spindle RPM = 6000, HP = 10

1) Bridgeport VMC1000XP/30 machining ctr

table size = 45” x 19”

travel: X=40”, Y=24”, Z=24”

tool carousal: 30 tools at max dia of 2.95”

spindle RPM = 6000, HP = 18

1) Bridgeport VMC1000/22 machining center

table size = 45” X 19”

travel: X=40”, Y= 20”, Z = 19”

tool carousal: 22 tools at max dia of 3.0″

spindle RPM = 6000, HP = 15

1) Bridgeport VMC1000/22 machining center

table size = 45” X 19”

travel: X=40”, Y= 20”, Z = 19”

tool carousal: 22 tools at max dia of 3.0″

spindle RPM = 4000, HP = 15

Equipment – CNC Lathes

1) Leadwell T6

14.7 HP, 5,000 RPM

17.7” swing, 16.5” between centers

collets (to 2.25” dia.)

6″ hydraulic 3 jaw chuck

2) Romi Centur 35E

10 HP, 3,500 RPM

20.25″ swing, 40″ between centers.

3J collets (1.75 dia. stock)

8″ 3 jaw chuck, 10” 2 jaw chuck

1) Romi PowerPath 15

15 HP, 4,500 RPM

17″ swing, 21.26″ between centers.

3J collets (1.75 dia. stock)

8″ hydraulic 3 jaw chuck

10” hydraulic 2 jaw chuck

12” manual 3 jaw chuck

1) Romi G260 turning Center

15 HP, 4,500 RPM

14″ swing, 21″ between centers.

8″ hydraulic 3 jaw chuck

1) Romi G30 turning center

30 HP, 2,500 RPM

24” swing, 40” between centers

12” hydraulic chuck, collets

3.5” thru spindle

Engine Lathes

1) Colchester, 15″ swing X 40″

3 & 4 jaw chucks, collets to 2″ dia, steady

rest

Vertical Milling Machines

2) Bridgeport ‘V’ram turret mills. Table 9” x 48”

Tooling: 90 deg head,boring heads, rotary

table, dividing heads, digital displays

Saws

1) FW Wells CNC production cutoff saw

capacity 9″ round or 9″ X 14″ flat

1) FW Wells manual cutoff saw, cap – 10″

round or 9″ X 16″ flat

1) Kalamazoo abrasive cutoff saw, 8″ blade

1) Grizzly cold saw, 12″ blade, cap – 4″ dia

1) Grob vertical band saw, cap – 18″ radius

Drill Presses

1) Clausing single spindle 20″

1) Clausing single spindle 15″

3) Wilton single spindle 14”

Welding

1) Miller 300 amp. AC‑DC gas tungsten‑arc.

1) Lincoln DC 250 M.I.G, T.I.G, & Arc

1) Plasma arc, capacity – 3/8″ stainless steel

1) Welding lathe for gas backed welding of

tube to fittings and turning of parts.

Finishing equipment

1) Hammond model 7VRO 7.5 H.P. polishing

lathe, 4″ wide X 168″ lg belt & 15″ dia buff

wheel

1) Dumore I.D. polisher – 5 HP

1) Baldor buffer 2 ‑ 12″ dia. X 3″ wide wheels

2) Burr King belt sander, 2” x 48”

1) Rockwell belt sander, 6” x 48”

1) Ensitech TBE-250 TIG brush

Misc. hand polishing equipment

Grinders

1) Clausing surface grinder 6″ X 18″ with

radius dresser

1) Cincinnati #2 cutter grinder

1) K.O. Lee universal cutter grinder

1) Oliver Ins. Co. drill sharpener 1/8″ to

5/8″ capacity

1) Sellers drill sharpener 1/2″ to 3″ capacity

Presses

1) Savage, 50 ton X 24″ stroke Hydraulic

1) 5 ton hydraulic

1) 3 ton arbor, ½ ton arbor

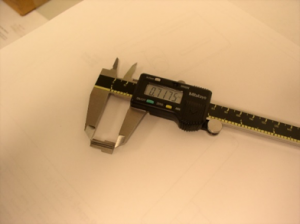

Inspection Equipment

* Mitutoyo 14″ X 10 or 20 power profile

projector with Geo-Chek Digital readout

* Mitutoyo model 211 surface roughness tester

* Micrometers and verniers to 48″

* 2) 24″ Mitutoyo Digital Height gauge

* Dial bore gauges to 6″

* Gauge pins, gauge blocks

* Granite inspection plate 36″ x 48″

* Steel layout table 60″ x 96″

Miscellaneous

* Pickup truck – F150

* 6000 lb. lift truck

* 1.5 H.P. magnetic base drill press

* Pipe threaders to 2″ NPT

* Torches

* 5″ portable bandsaw

* Air and electric grinders

* Bead blasting

* Wide variety of hand tools

* High speed milling head

* Electroetch marking