Bag in Box Filling Machines

Bag in Box Filling Machines

Purpose of the filling machine:

The model M125 filler is used to fill products like milk, ice cream mix, soft drink syrups, edible oils, sauces and more into containers such as flexible bags with a port and open top pails.

General Description Of Filling Machines:

Materials used for construction are industry approved. Cabinet, stand, roller table and brackets are made of type 304 stainless steel. All product contact surfaces are made of type 304 or type 316 stainless steel with sanitary welds and polished to a #4 satin finish all over. The turbine flow meter is made of type 316 and 17/4 stainless steel with a Rulon 641 bearing. Product contact gaskets and o’rings are made of Buna-N and Viton. Machine logic and operator interface are field proven Allen-Bradley components. Major pneumatic components are by SMC and Bimba Mfg.

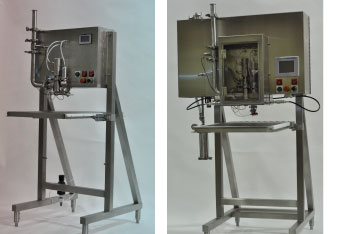

Configurations:

Several configurations are available, the most common one is shown on the left. This is the industry standard M125. It has a single fill head, bag holder and capper mechanism. The picture to the right shows the model M125-ESL (Enhanced Shelf Life). It has added features such as a positive air flow fill chamber, spraying system for sanitizing solutions, pre-fill vacuum and post-fill nitrogen.

Other configurations include:

- Twin Head filler with one left hand cabinet assembly and one right hand cabinet assembly mounted to a common stand.

- Dual Head filler with a left hand and right hand filling station mounted on a common cabinet and stand.

- Single Head Enhanced Shelf Life filler with features such as a hooded fill area, pre-fill vacuum and post-fill nitrogen.

- A turbine flow meter is standard; however, a mag meter, mass flow meter or weighing device can be substituted.

Features: (dependant on machine configuration)

- Automatic start if selected, auto decap and recap, auto spout eject after recap.

- User control, via the Allen-Bradley PanelView interface, of the C.I.P. timing functions, recap pressure time, pre-fill vacuum time, post-fill drip time and post-fill nitrogen time.

Specifications:

- Electrical Requirements – 120VAC, 50/60 Hz, 5 Ampere

- Compressed air supply – 70 to 80 psig

- Dry cycle time (uncap to recap) – approx 3 seconds

- Fill capacity – 1 gallon to 1200 gallons

- Product flow rate – 10 GPM to 70 GPM using a turbine flow meter

- Volume control – 1” or 1 ½” turbine flow meter